Published - 28th Oct 2015

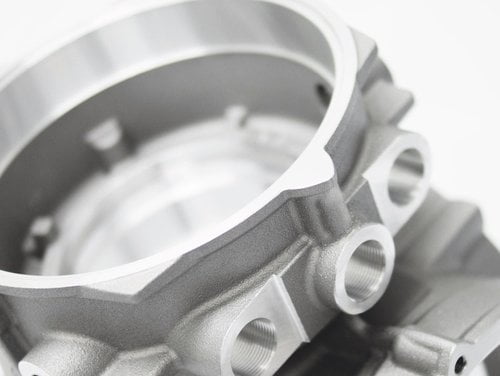

Machining is used to introduce features that cannot be produced during the casting process. This is due to the very small tolerances of the design dimensions. In these instances, a ‘machining allowance’ is incorporated at the design stage so that the casting can eventually be machined back to the exact dimensions.

Machining takes place once any fettling or heat treatment has been completed but before any finishing processes, such as anodising or painting. Machining is carried out by computer numerical control (CNC). Specialist computers are programmed to guide the machining tools and shape the component accordingly.

Haworth Castings offers the full range of machining services, which includes turning, milling, grinding, drilling and inspection.

Here is a summary of each of the processes:

In turning, carbide or ceramic cutting tools are used to create a smooth finish on the casting. These tools have good wearability, with long life and repeatability.

The component is positioned in a chucking (turning) fixture and rotated using either a vertical or horizontal machine. Using the tools, any unwanted material can be removed from the inside and outside of the casting to produce turned bores (holes) and diameters to close tolerances, with a high standard of finish.

In milling, the component is securely clamped to the machine table. The cutting tools, which use changeable carbide or ceramic inserts, move and rotate at optimum speed across the work piece to generate various features on the face of the casting. This can be carried out on a horizontal or vertical axis.

Traditionally, turning and milling have been carried out separately but we also have machines that can now perform both operations together – reducing set-up/tooling times and costs.

Surface grinding is used to produce a precision flat finish. The component is secured on a magnetic plate or, with non-ferrous castings, a holding fixture. The outside edges of the castings are ground using a carborundum grinding wheel, which revolves at a rapid speed to produce the required finish.

Manual drilling is used to drill or tap holes into the component. The positioning of the holes is determined using cast dimples which are introduced during casting manufacture or by bespoke drilling fixtures.

The final stage of the process is designed to check that the machining work meets the specified criteria. Casting inspection is carried out using automated equipment and probes during the machining process and post manufacture.

To find out more about our specialist machining expertise, please email us today at: sales@haworthcastings.co.uk or call +44 (0)1794 512685.

If you have a project, talk to our experienced sales team

Contact us