Published - 24th Nov 2016

In this blog, we turn the spotlight on milling – one of the most popular machining techniques used at Haworth Castings.

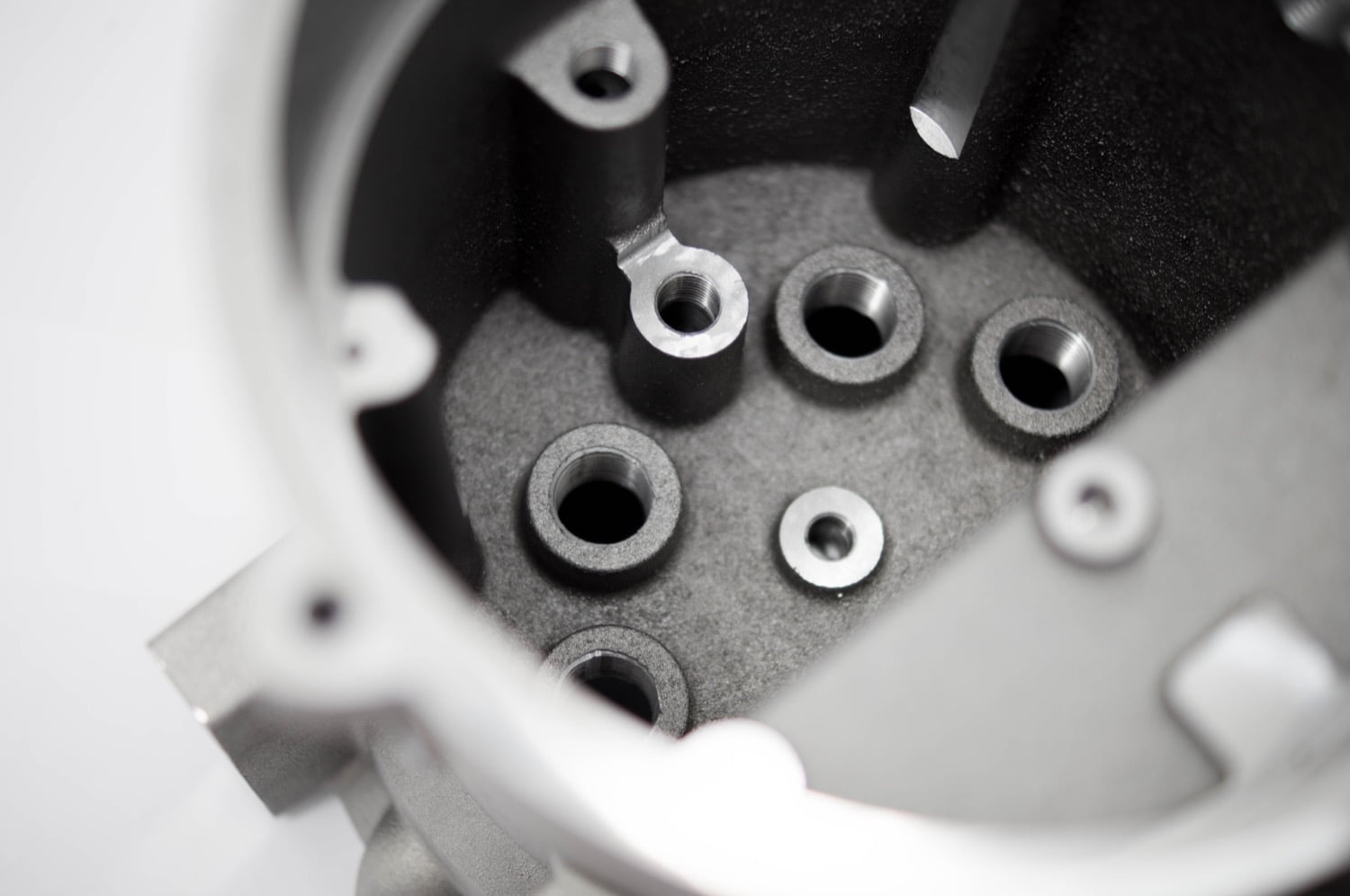

Milling removes material from a workpiece to add machined features that cannot be produced during the casting process. It can machine parts to high tolerances and precise surface finishes.

The process can be carried out manually – with the engineer controlling the movement of the milling machine. Nowadays, however, milling is more frequently carried out using computer numerical control (CNC) machines – which are pre-programmed to control the movement of the workpiece and the cutters. This is how the bulk of our milling work is completed at Haworth Castings.

The cutting tools can be manufactured from a range of materials, including high-speed steel and ceramic carbide. Carbide is more expensive than high-speed steel but it is also more hardwearing – which prolongs the tool life and ability to repeat it. The choice of cutter is dependent on the features required and the material of the workpiece.

Firstly, the component is clamped to either a milling fixture or directly on the table in a CNC milling machine, depending on the requirements. It is fed into a rotating cutter to remove the required material and produce the features that cannot be cast onto the piece.

During the milling process, the engineer must ensure that the workpiece is clamped to the fixture securely without causing distortion. This is vital otherwise inconsistencies with the shape and dimensions may result.

Milling can be carried out on either horizontal or vertical machines. Horizontal machines are often more popular because features can be machined onto multiple surfaces without resetting the component while vertical machines can only work on one surface (the upper side) at a time.

To find out more about our milling capabilities, call us today on +44 (0)1794 512685 or email: sales@haworthcastings.co.uk

If you have a project, talk to our experienced sales team

Contact us