Published - 11th Apr 2017

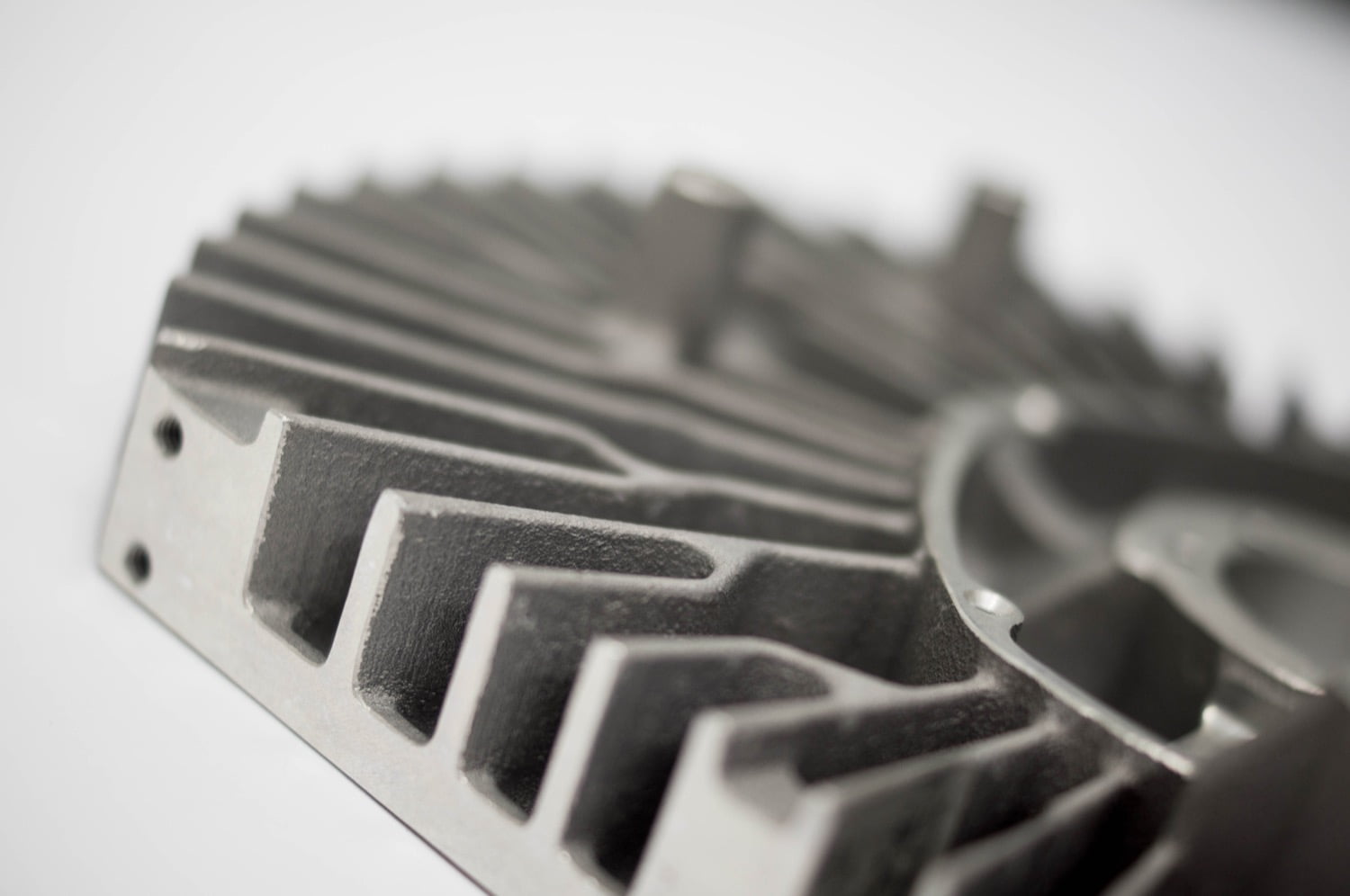

Non-destructive testing (NDT) is the process of inspecting, testing and evaluating components or materials for discontinuities or flaws, such as cracks and inclusions. NDT plays an important role in ensuring that components work in a safe, reliable and consistent manner. For this reason, it has many applications in engineering to test components used in bridges, cars, trains, planes and many other objects all around us.

Importantly, NDT enables us to test components without causing damage so that they can still be used. This makes NDT a cost-effective process for product or part evaluation.

The history of NDT can be traced back to the beginning of the twentieth century. An early crack detection method was first used in the railroad industry to locate cracks in heavy steel parts. NDT has evolved significantly since then and it now encompasses a wide range of techniques such as ultrasound, electromagnetic radiation and liquid penetrant testing.

At Haworth Castings, we offer a comprehensive range of testing services to ensure that each individual component meets exacting specifications. NDT can be carried out post-production as an additional service. This decision is made by the customer, depending on the end application. For example, NDT would be needed for safety-critical parts.

Our NDT work is carried out at a third-party test facility run by Inidam, which specialises in this work. NDT provides our customers with independent verification of part integrity.

This work falls into two main categories – radiographic imaging and dye penetrant testing.

Radiographic inspection is a highly effective method for identifying defects. X-rays are projected at the casting to reveal any internal defects or variations in quality. Traditionally, film techniques have been used but, increasingly, digital techniques are now becoming more popular.

Dye penetrant testing is another method to detect cracks, porosity or other surface discontinuities in various materials. The castings are dipped into a penetrant testing liquid and inspected under ultraviolet light. This liquid contains particles that fluoresce if any defects are present.

In future blogs, we will be looking at each of these processes in turn – assessing their respective uses and merits in our metal casting work.

At Haworth Castings, we offer a wide range of testing and inspection services for sand and gravity-die castings. Contact us today at sales@haworthcastings.co.uk or call +44 (0)1794 512685 to find out more.

If you have a project, talk to our experienced sales team

Contact us